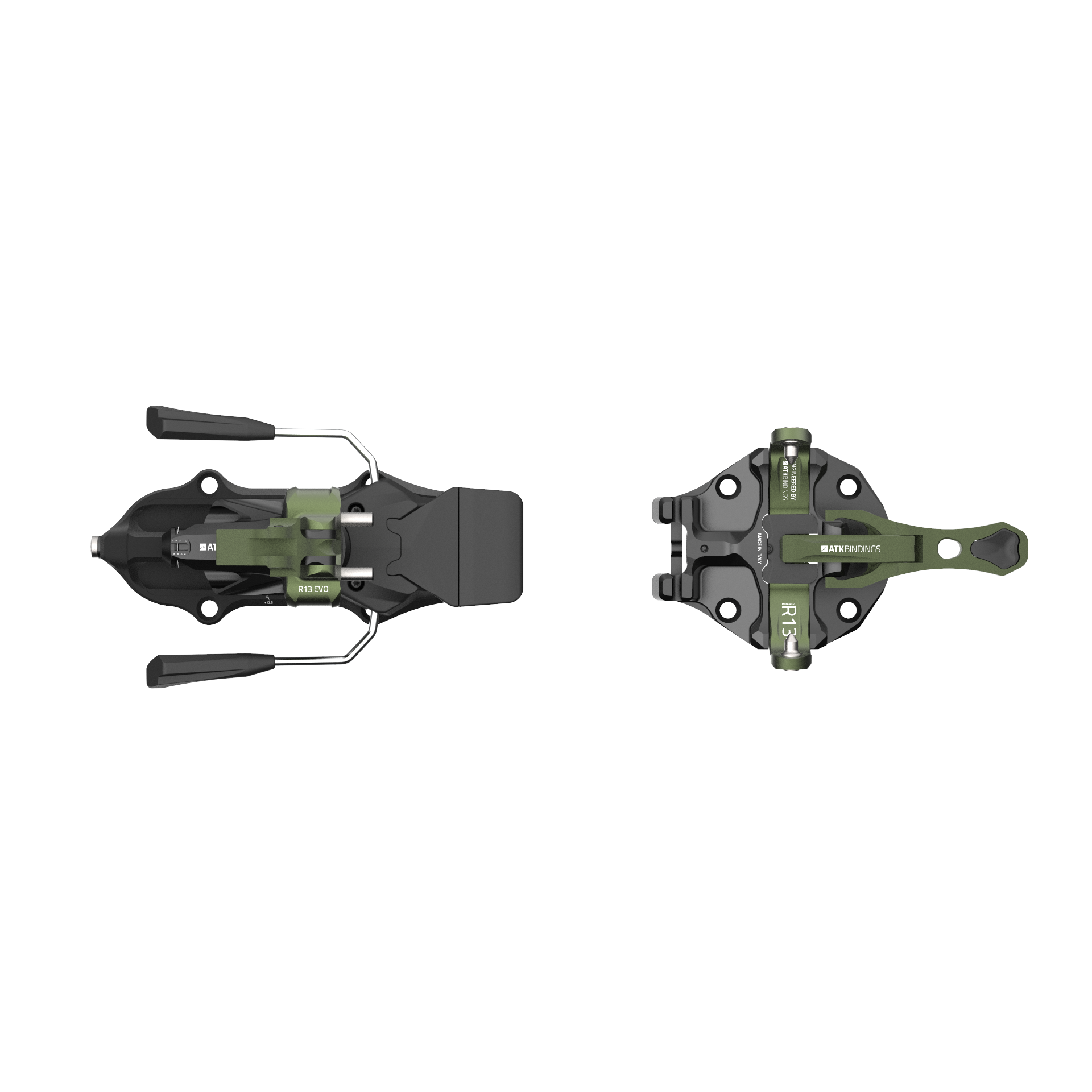

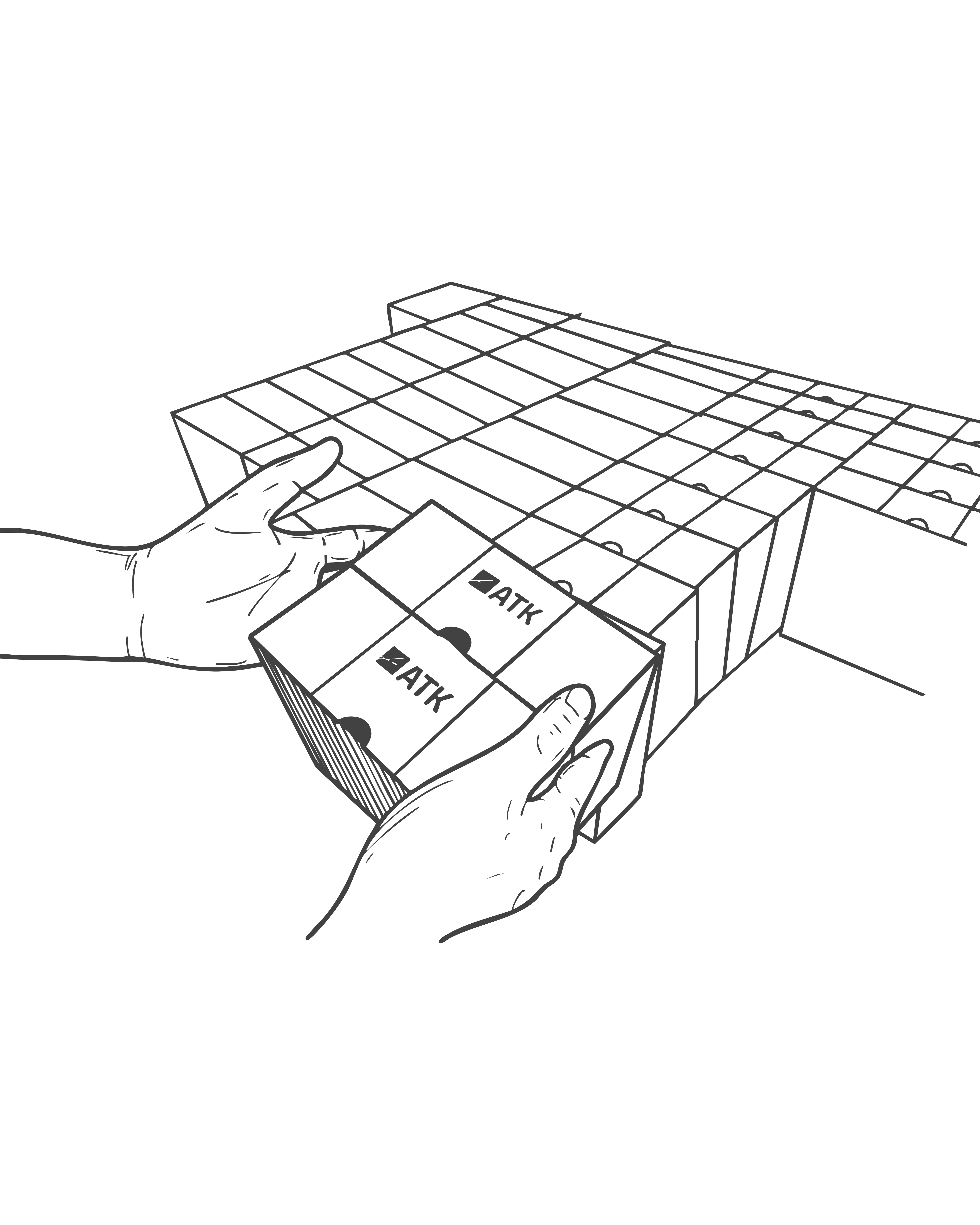

Mission

At ATK Bindings, our mission is to enhance the skiing performances of enthusiasts of all levels by designing and producing lightweight bindings.

Vision

We aspire to create a world where skiers can effortlessly explore their passion for the mountains, thanks to the lightweight design of our products. We will achieve this goal by relentlessly pursuing innovation and becoming the global leader in the world of inline binding.

Family

ATK was born into a family that instilled it with its own set of values. They have guided us through the years, the changes, and the challenges that our growth forced us to confront. These values are the foundation that sustained all our efforts in reaching our goal: creating performance through lightness for you.

Inclusivity

Skiers' needs are the driving force behind our constant strive for improvement. Our strength comes from the thorough effort we put into understanding all the inputs that can feed our ever-going development process and help us tailor light products to unlock your best performance.

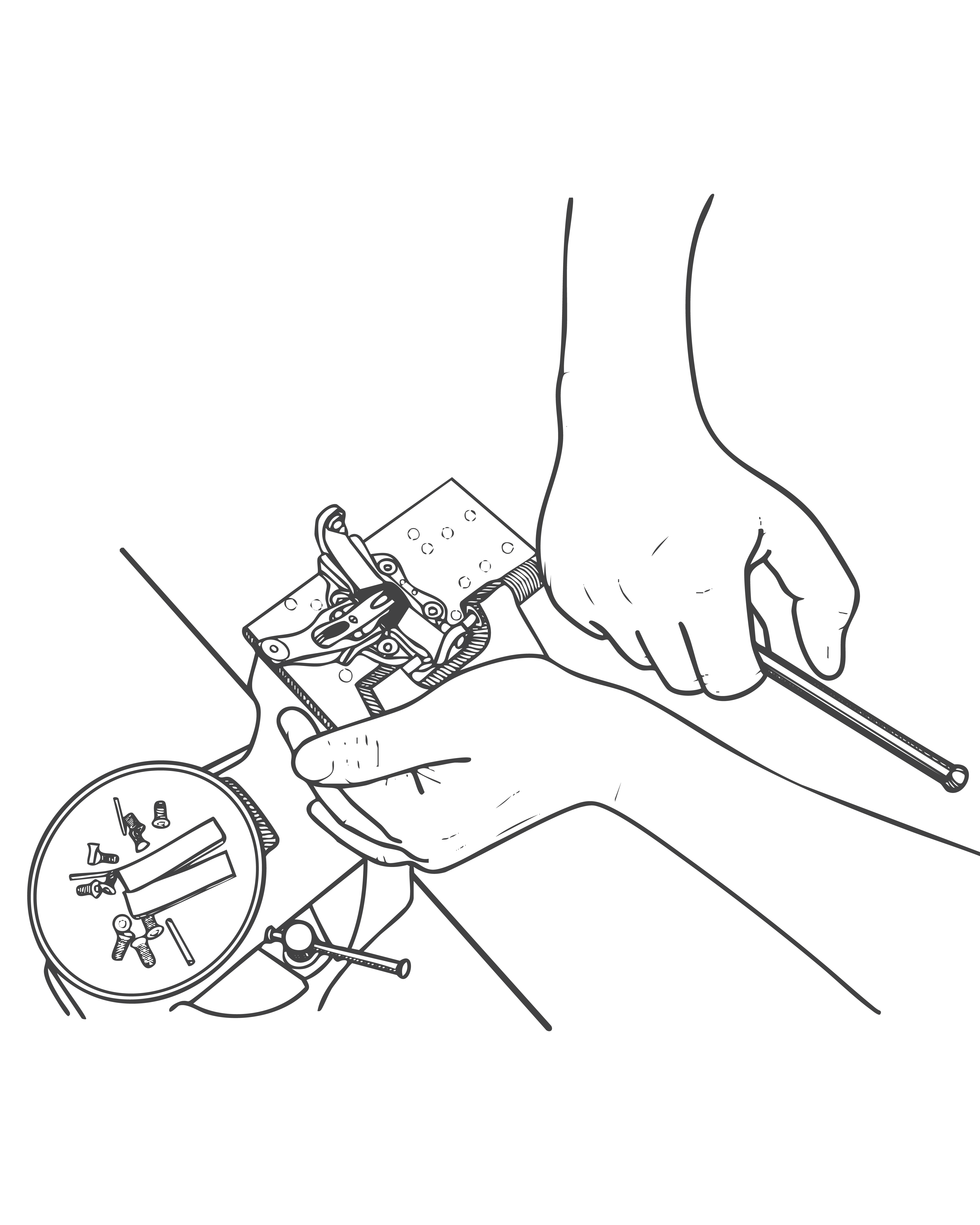

Lightness

Our strength is in the lightness that allows you to enjoy all the aspects of the ascent and have the most fun on the descent. This isn't casual; it's the result of all the years that ATK spent experimenting in the Race world. Years of activities revolved around one guiding philosophy 'Performing Through Lightness!'